Non-destructive testing

In-depth structural control

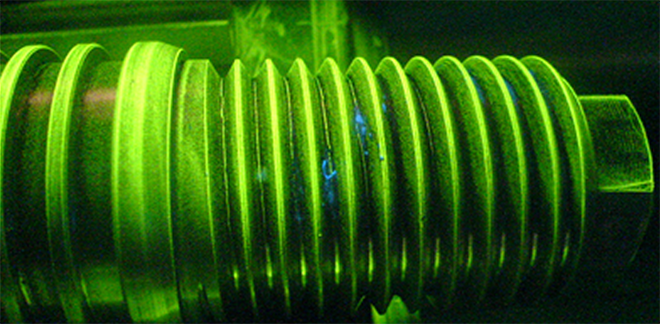

Ultrasound (UT)

Ultrasound detects internal and external defects in various materials. Our automated immersion system (6 axes) and advanced technologies (multi-elements, ToFD) enable precise analysis to ensure the conformity of inspected parts.

Detecting surface defects

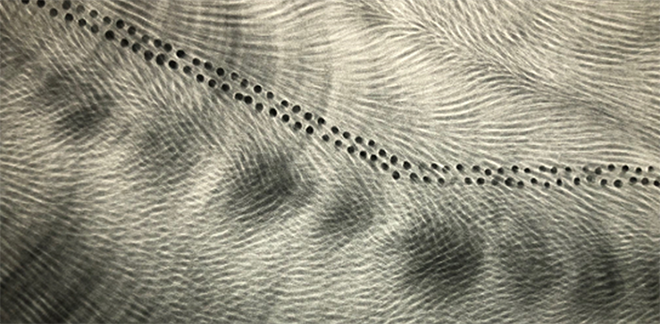

Magnetic particle inspection

Magnetic particle inspection detects defects close to the surface of ferromagnetic metals. Our magnetic test bench (4000A, 2m50) allows current, coil or magnetic field testing, guaranteeing reliable detection.

Detecting surface defects

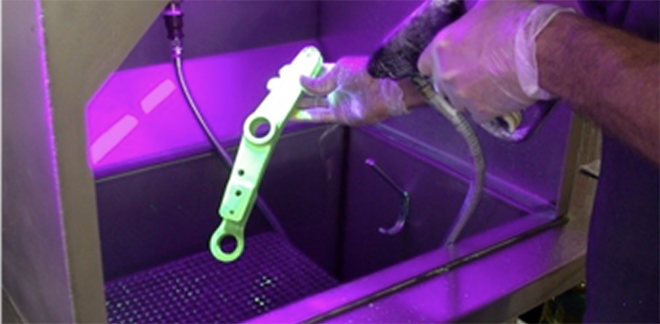

Penetrant testing

Penetrant testing is a non-destructive testing method used to detect cracks, porosity, or open surface defects in metallic or non-metallic materials (plastics, ceramics, etc.). It is particularly effective for identifying discontinuities invisible to the naked eye.

Internal material analysis

Film and non-film radiography

We carry out X-ray and gamma-ray inspections to identify internal discontinuities in all types of materials. Thanks to digital techniques, results are obtained in real time, enabling rapid analysis and effective intervention according to project requirements.

Conductive materials inspection

Eddy currents

This method identifies internal and external defects in conductive materials. Thanks to multi-frequency inspection and the use of high and low frequencies, we obtain a detailed analysis enabling us to assess structural integrity and anticipate possible corrosion or cracking problems.

Surface and finishing inspection

Visual controls

We analyze appearance and surface defects on all types of materials. These checks identify irregularities, corrosion, defective welds, or imperfect coatings, guaranteeing the conformity and durability of the equipment inspected.